Polypropylene MB Media

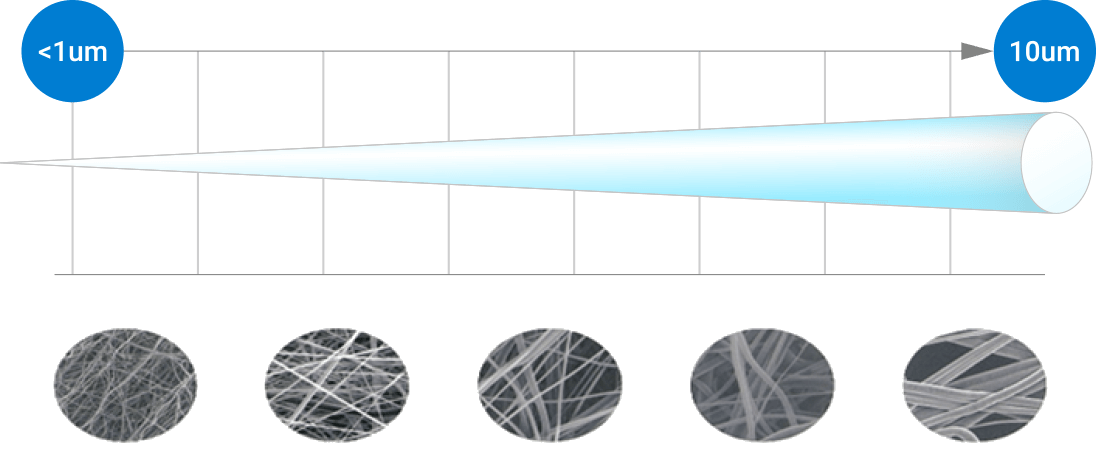

Manufacture of various grades of filter materials through control the diameter between 0.6 ~ 10um

Mask Filter

Liquid Filter

Air Filter

Polypropylene

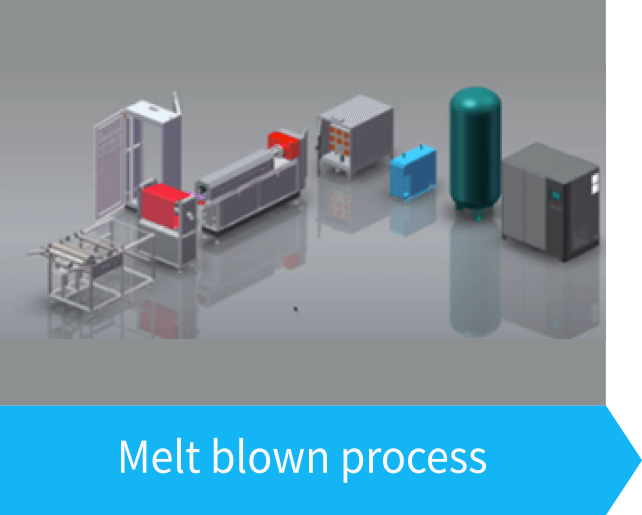

Melt-Blown Media

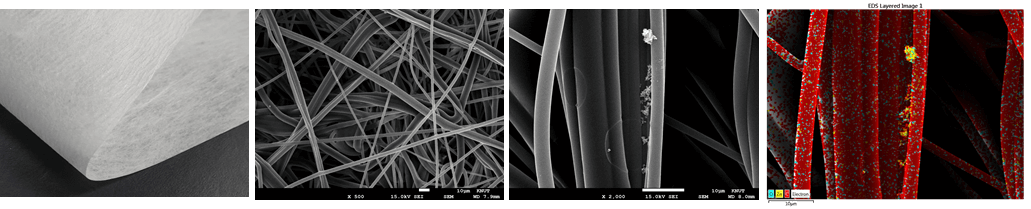

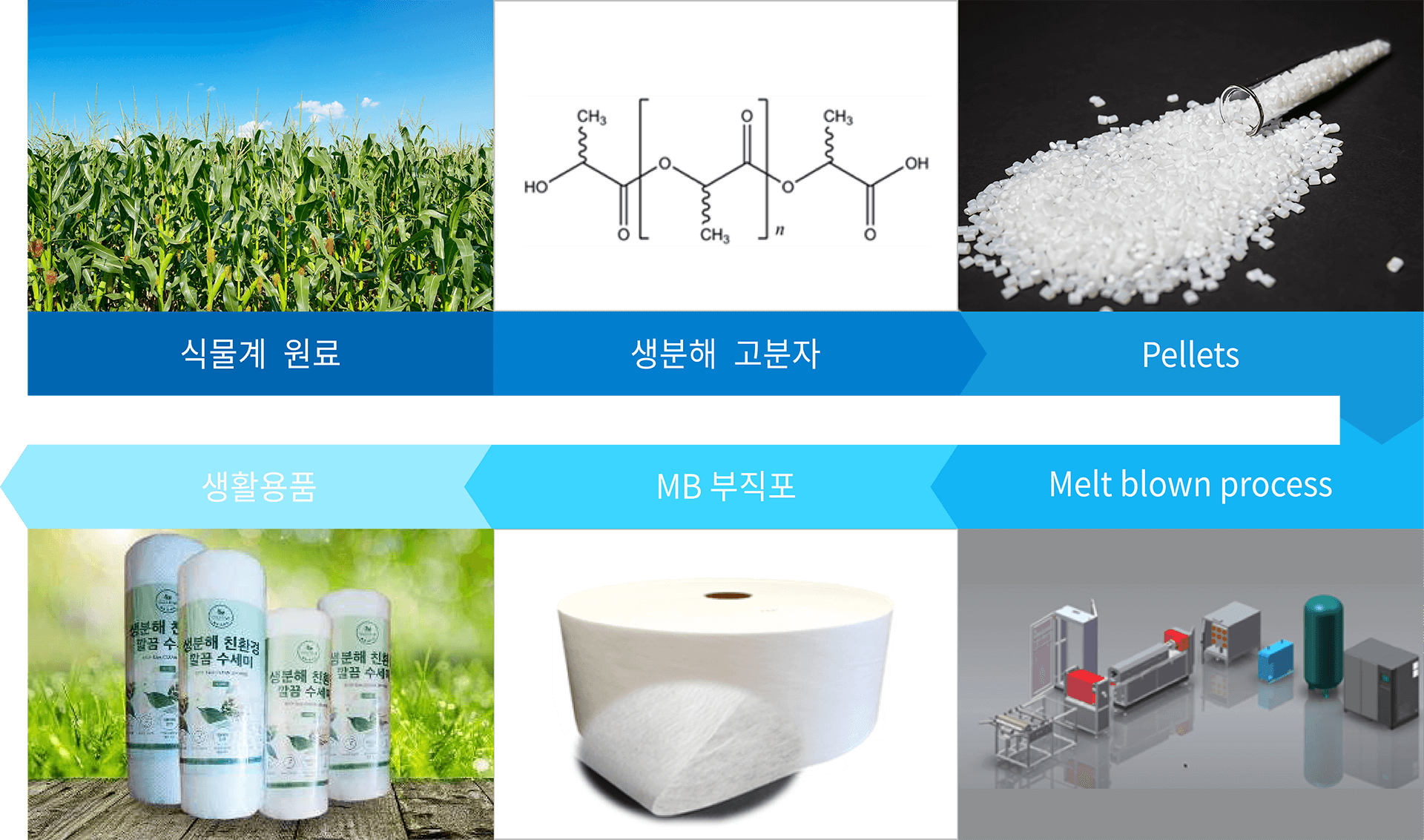

In the stage of the melting is pressing out thorough the nozzle, high-temperature and high-pressure air is applied to stretch and microfine the fibers to create microfibers ranging from hundreds of nanometers to tens of micrometers, and each fiber is randomly laminated to form a porous web.

Melt-blown material is a porous material with fine and uniform pores and is used as a core material for mask filters, air filters, oil absorbent fabrics and liquid filters.

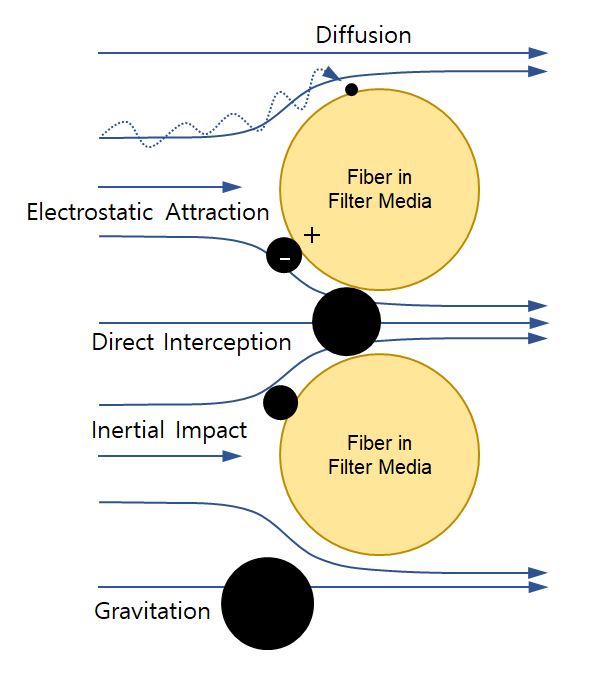

Mask Filter and Air Filter are purpose to remove fine particles in the air and it is required secondary treatment for electrostatic effect to perform low differential pressure with high-efficiency. ABSFIL apply Water Hydro Charging technology to static electricity on the melt-blown material, and compared to the conventional Corona Charging and Plasma Charging, there is almost no static discharge and the shelf life is longer.

While the reduction in electrostatic force due to water hydro charging is about 2% per year, it is reported that the quality change due to temperature and moisture in products made with conventional technology is extreme even within a few days. Particle Removal Mechanism in liquid filtration is an application where physical filtration by Direct Interception Effect dominates, and in order to realize low differential pressure, long life and high efficiency, fibers constituting the melt blown material Technology to minimize the thickness of (fiber) is required.

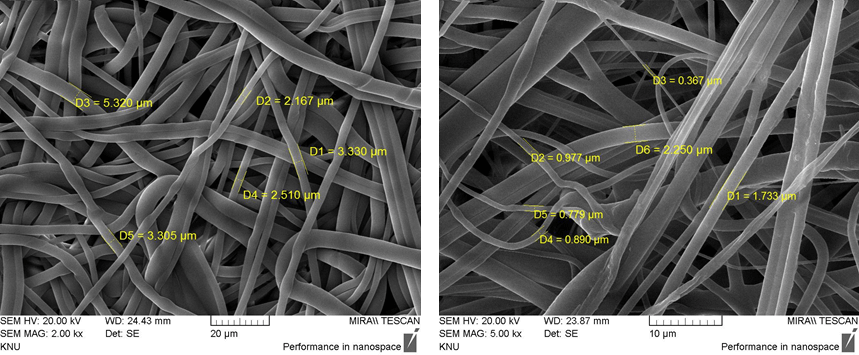

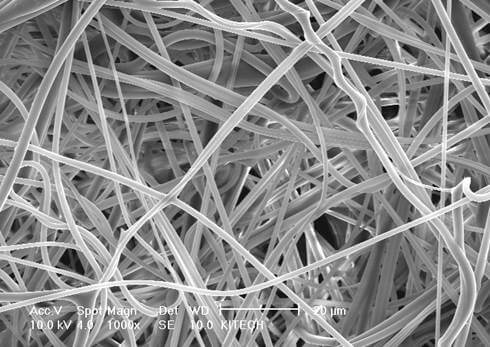

Generally, the fiber diameter of melt blown material is around 3~5㎛, and our company is realizing a minimum diameter of 700nm by using resin blending technology and ultra-fine nozzle technology. Compared to conventional materials, melt blown materials completed with this technology form less than half the differential pressure under the same removal efficiency conditions, and it has been confirmed that the filter life is more than doubled.

ABSFIL apply Water Hydro Charging technology to static electricity on the melt-blown material, and compared to the conventional Corona Charging and Plasma Charging, there is almost no static discharge and the shelf life is longer. While the reduction in electrostatic force due to water hydro charging is about 2% per year, it is reported that the quality change due to temperature and moisture in products made with conventional technology is extreme even within a few days.

Particle Removal Mechanism in liquid filtration is an application where physical filtration by Direct Interception Effect dominates, and in order to realize low differential pressure, long life and high efficiency, fibers constituting the melt blown material Technology to minimize the thickness of (fiber) is required.

Generally, the fiber diameter of melt blown material is around 3~5㎛, and our company is realizing a minimum diameter of 700nm by using resin blending technology and ultra-fine nozzle technology. Compared to conventional materials, melt blown materials completed with this technology form less than half the differential pressure under the same removal efficiency conditions, and it has been confirmed that the filter life is more than doubled.

Mask Filter and Air Filter are purpose to remove fine particles in the air and it is required secondary treatment for electrostatic effect to perform low differential pressure with high-efficiency.

ABSFIL apply Water Hydro Charging technology to static electricity on the melt-blown material, and compared to the conventional Corona Charging and Plasma Charging, there is almost no static discharge and the shelf life is longer.

While the reduction in electrostatic force due to water hydro charging is about 2% per year, it is reported that the quality change due to temperature and moisture in products made with conventional technology is extreme even within a few days. Particle Removal Mechanism in liquid filtration is an application where physical filtration by Direct Interception Effect dominates, and in order to realize low differential pressure, long life and high efficiency, fibers constituting the melt blown material Technology to minimize the thickness of (fiber) is required.

Generally, the fiber diameter of melt blown material is around 3~5㎛, and our company is realizing a minimum diameter of 700nm by using resin blending technology and ultra-fine nozzle technology. Compared to conventional materials, melt blown materials completed with this technology form less than half the differential pressure under the same removal efficiency conditions, and it has been confirmed that the filter life is more than doubled.

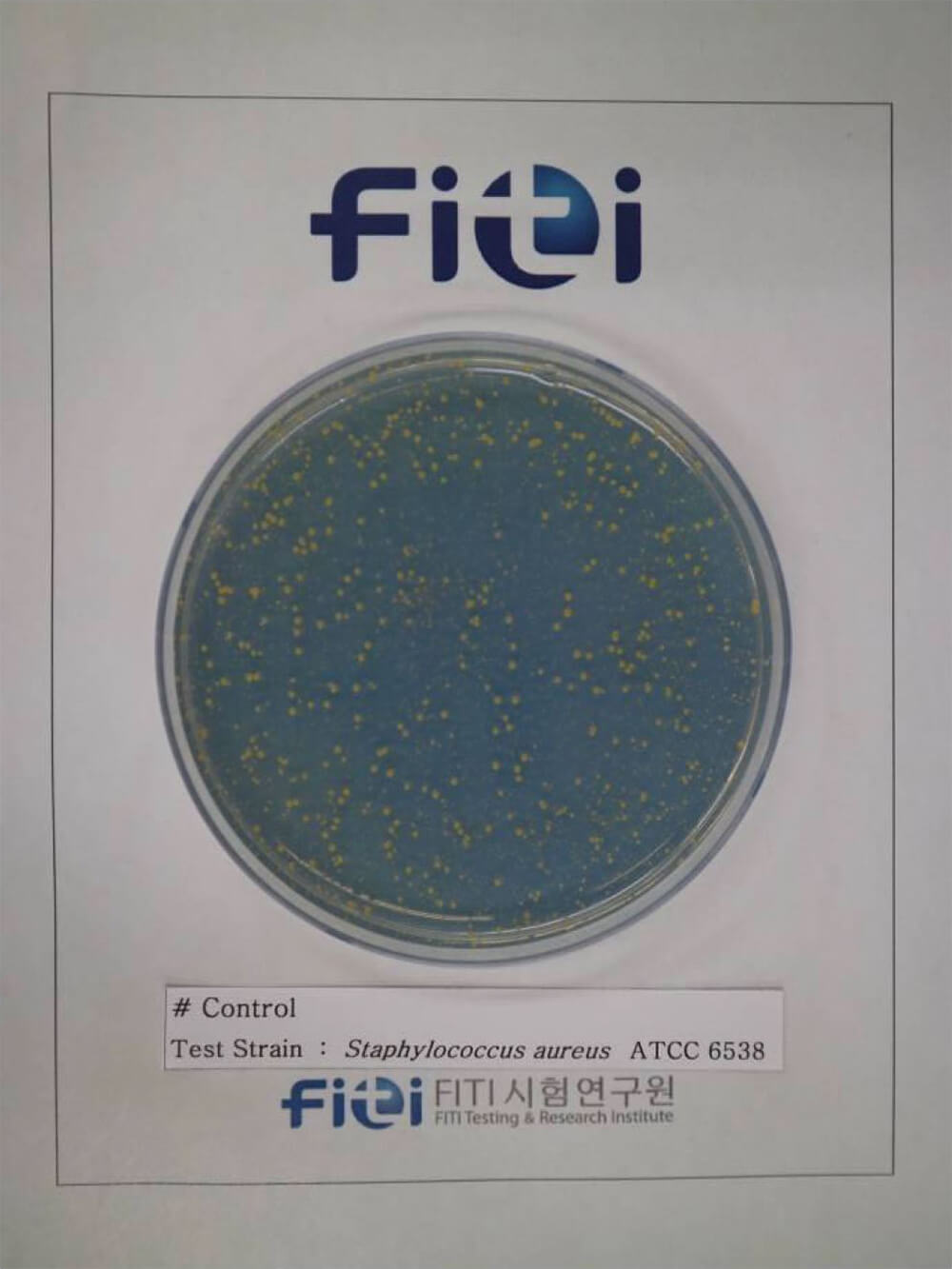

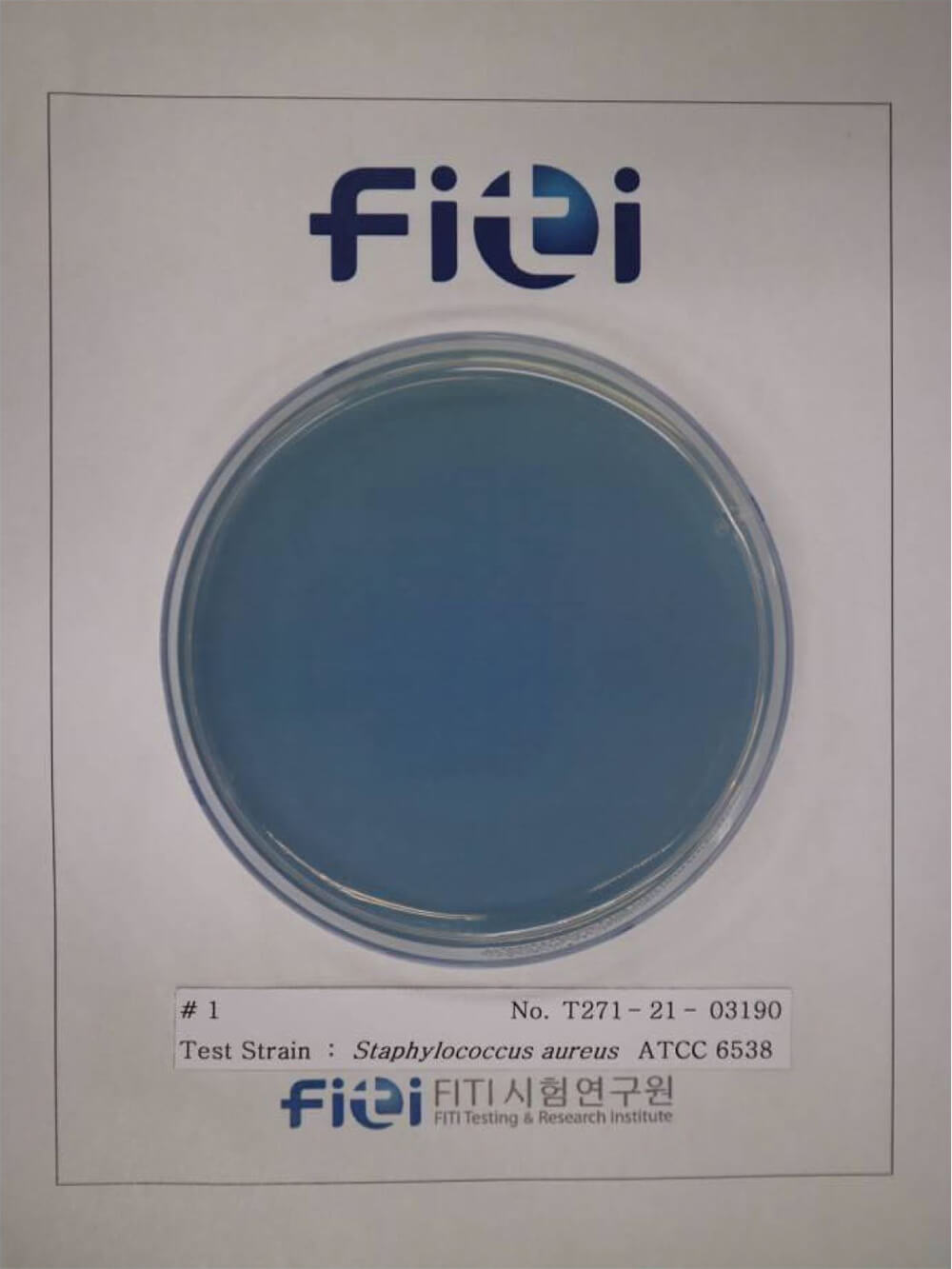

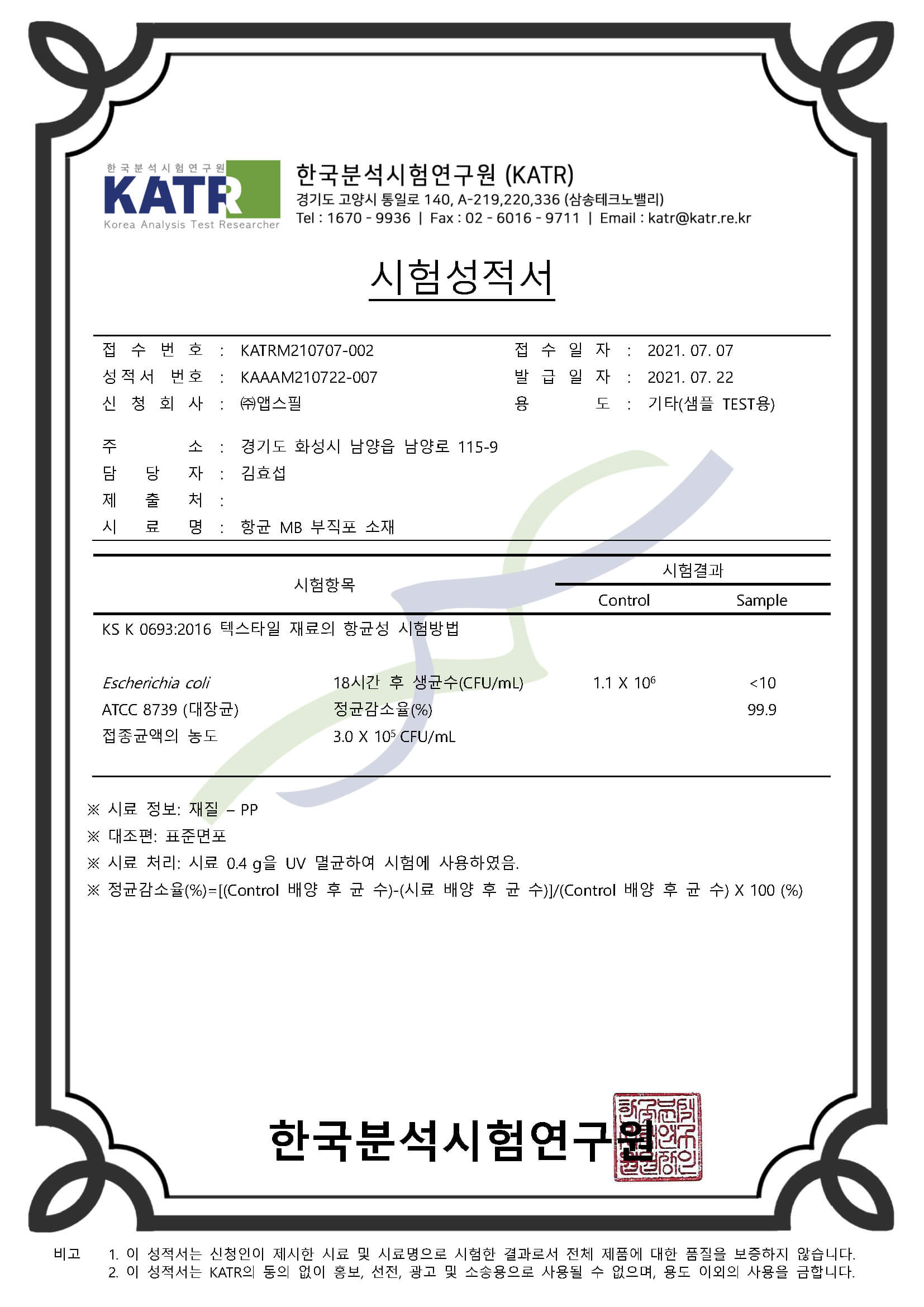

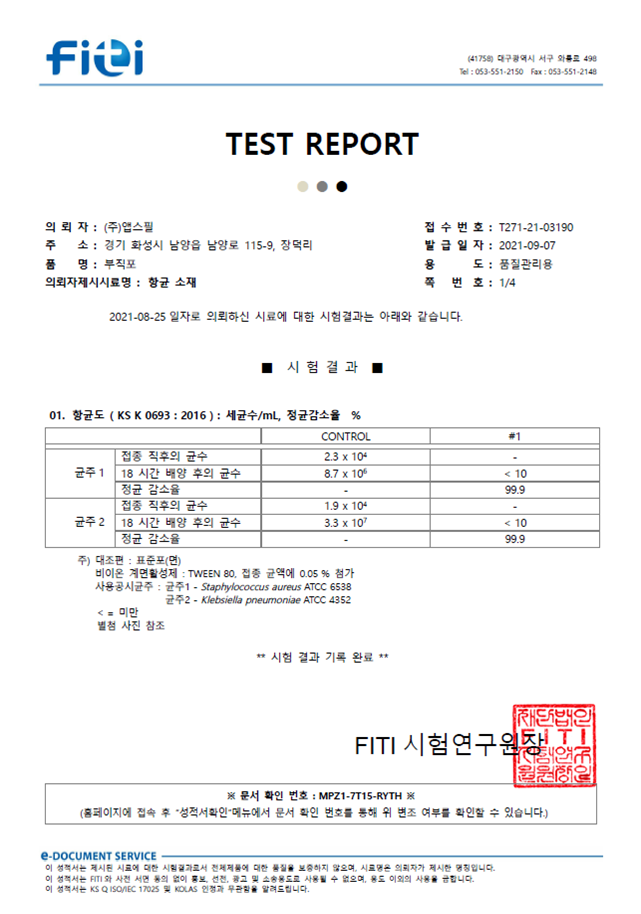

(ATCC 6538, Staphylococcus aureus)

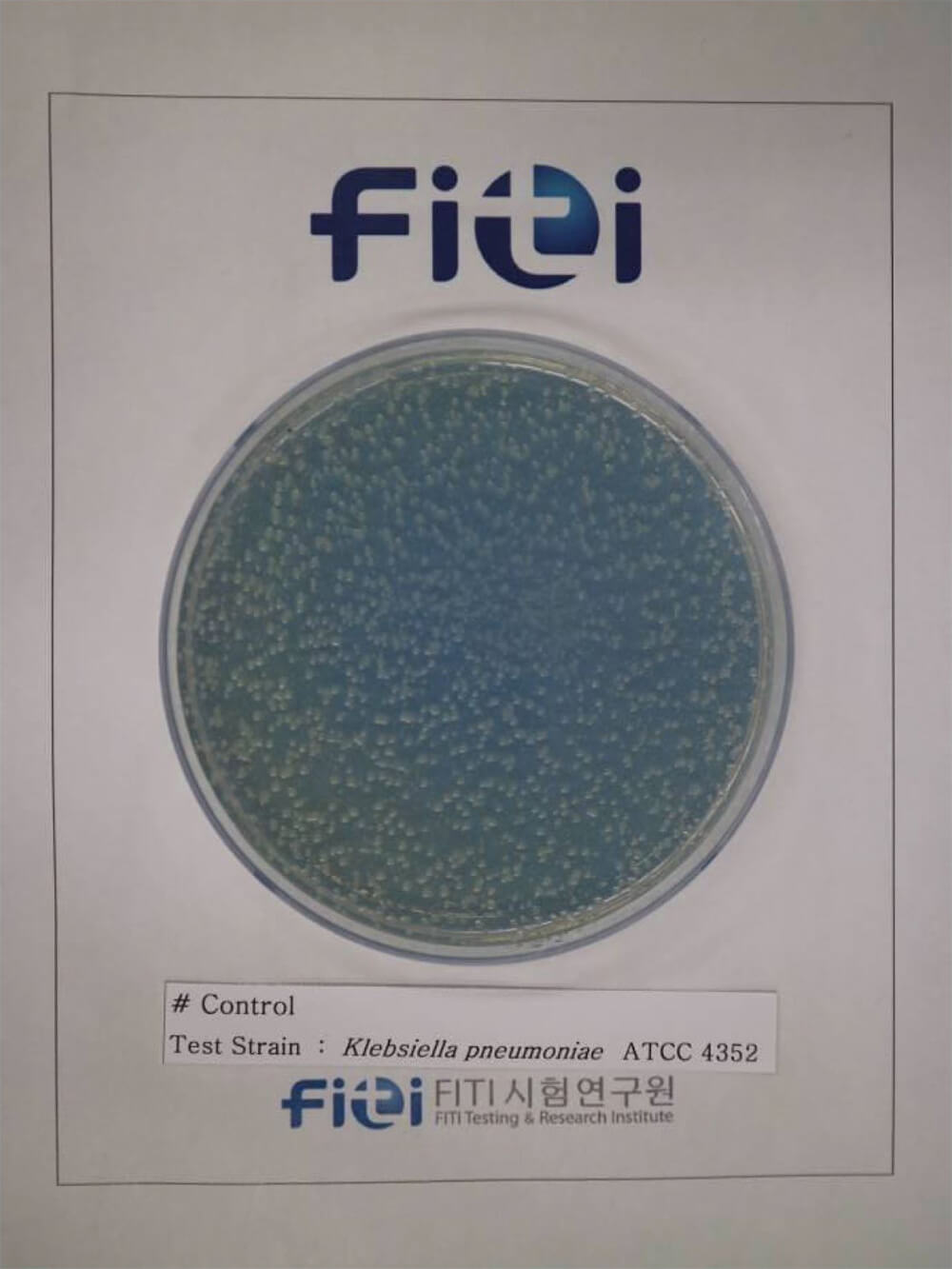

(ATCC 4352, Klebsiella pneumoniae)

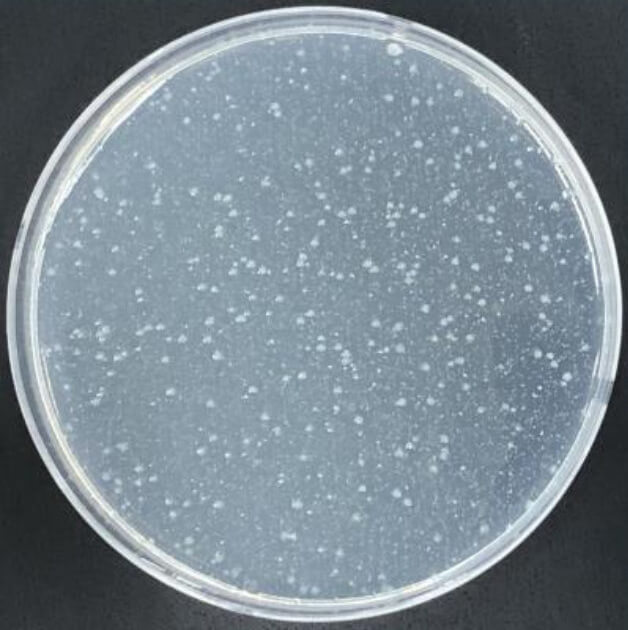

(ATCC 8739, Escherichia coli)

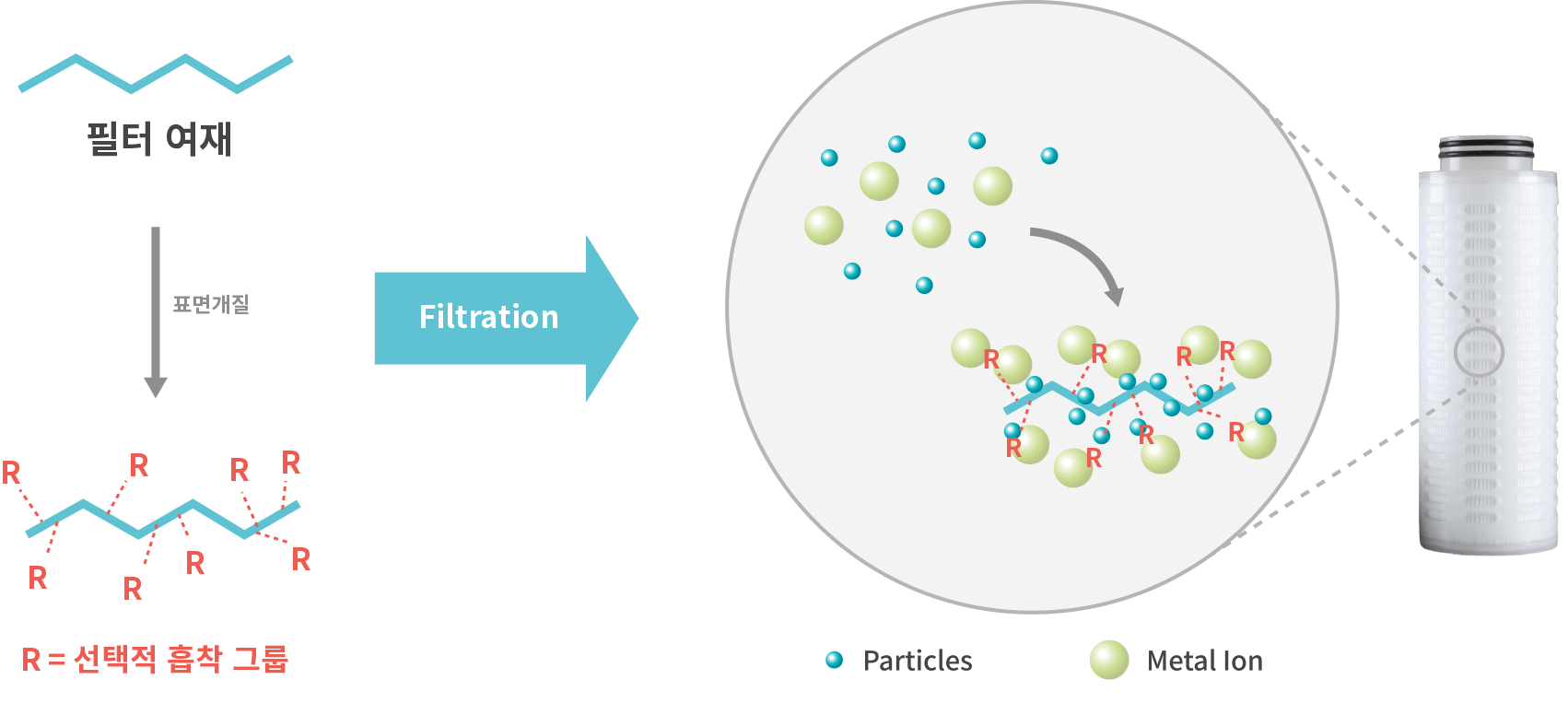

Supply best suitable materials according to the industrial area through surface hydrophilization and selective absorption.

and polymerization technique.

Eco-friendly leather / Fabric material_FreeTexkin®

Structure

FreeTexkin®

Development concept (Only One Product)

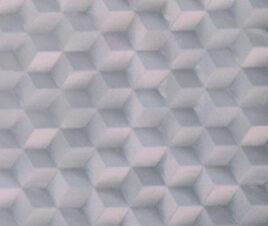

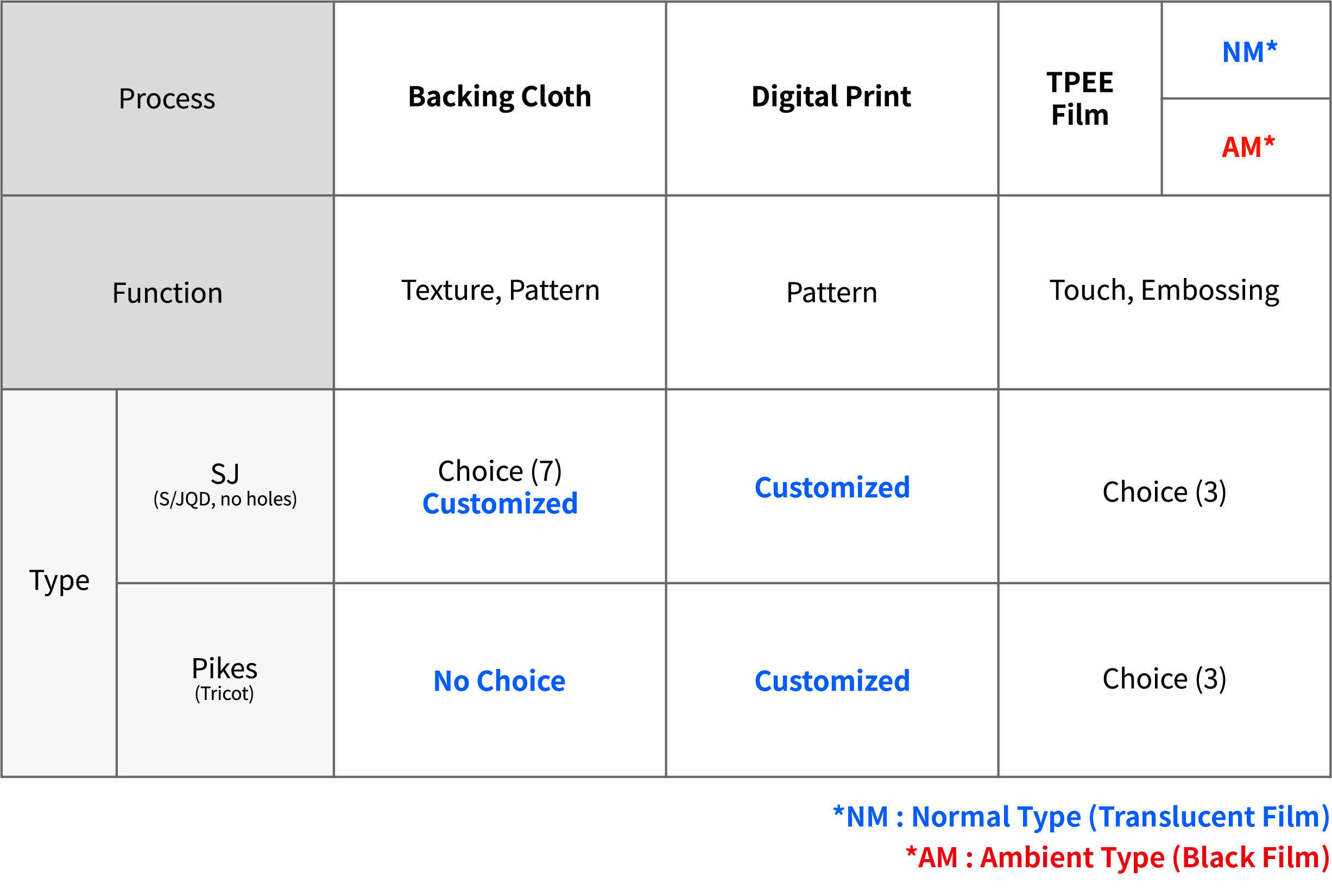

1) Customized Design(BESPOKE) : Various Fabric, DTP, TPEE (Option: Silicone anti-staining coating)

3) Hybrid material : Fabric & Film

Strengthen advantage of Fabric : Texture, Color, Pattern

Supplement for the shortcomings of the fabric: wear and tear (film)

4) Low MOQ : 100m

FreeTexkin fabric

STONE BEIGE

BIG FLOWER

STONE BLUE

SMALL FLOWER

FT-DOT

FT-FORMAL

FT-3D

FT-STONE(BLUE)

FT-BABY ILLUST

USE

Furniture and Interior (Prop, Art wall and so on.) ㆍsundry goods, bag, Shoes, Clothes.

Develop Customization / Choice type of Pattern

Prompt response to customer requirement as all the materials (including fabric, DTP, TPEE Flim) of FreeTexkin manufacturer by ourselves.

ㆍHow to : Customized Pattern Development Process (BESPOKE)

ㆍProduction

ㆍSimplified and shortened production process

ㆍMinimal water used, minimal wastewater generated

Increased Welfare of Manufacturing Workforce

ㆍReduced exposure to chemicals

Added Recycled Content

ㆍReusing valuable materials – saving raw materials

→ Recycled polyester (backing fabric); optional

ㆍProduct

Eco-friendly certification

Non-toxic Material

ㆍNO PVC

ㆍNO DME, NO MEX

ㆍSolvent-free

ㆍMinimal VOC

ㆍNO Plasticizers, NO phthalates

ㆍNO formaldehyde

ㆍNO antibacterial additives

ㆍFlame retardant without halogens